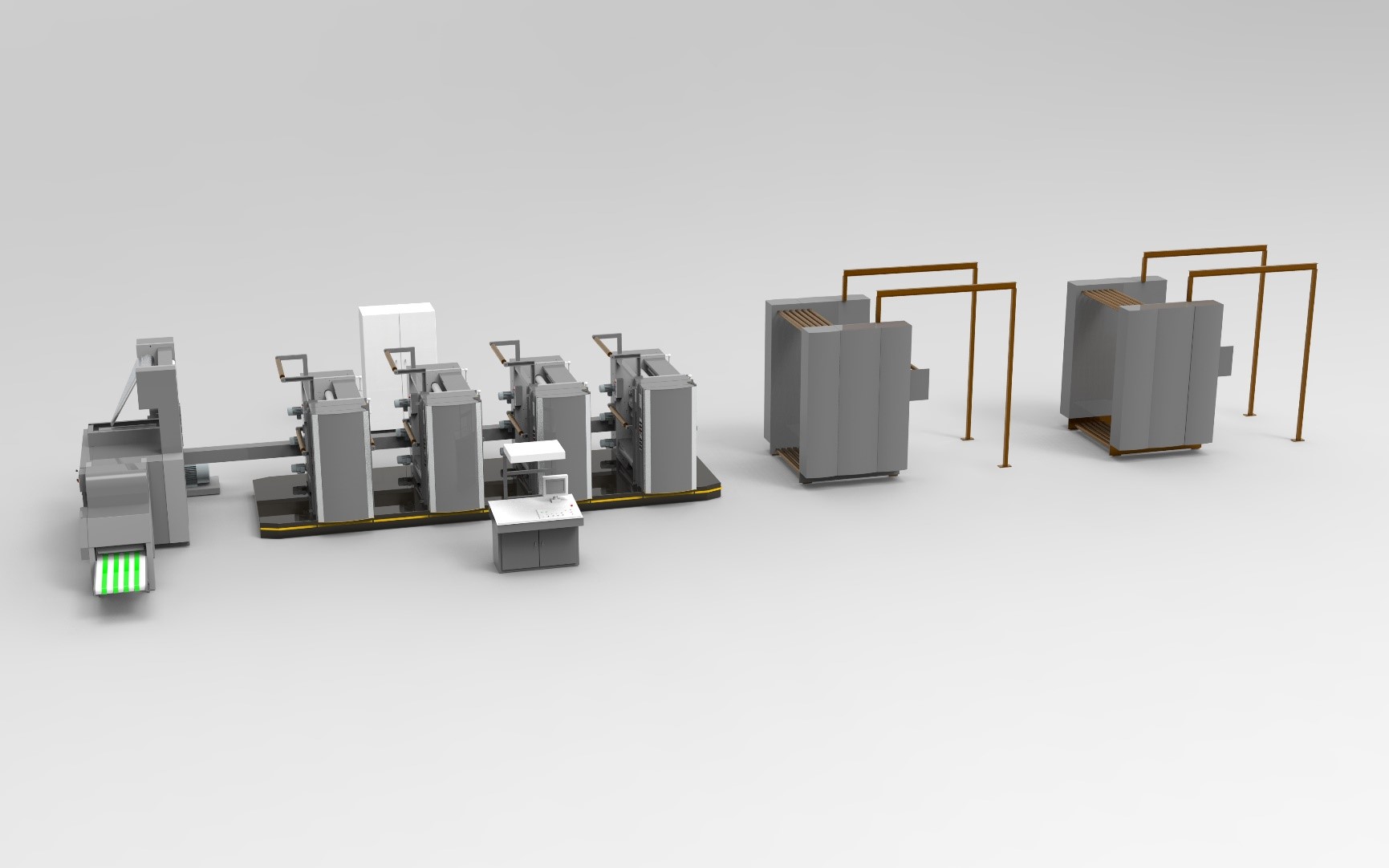

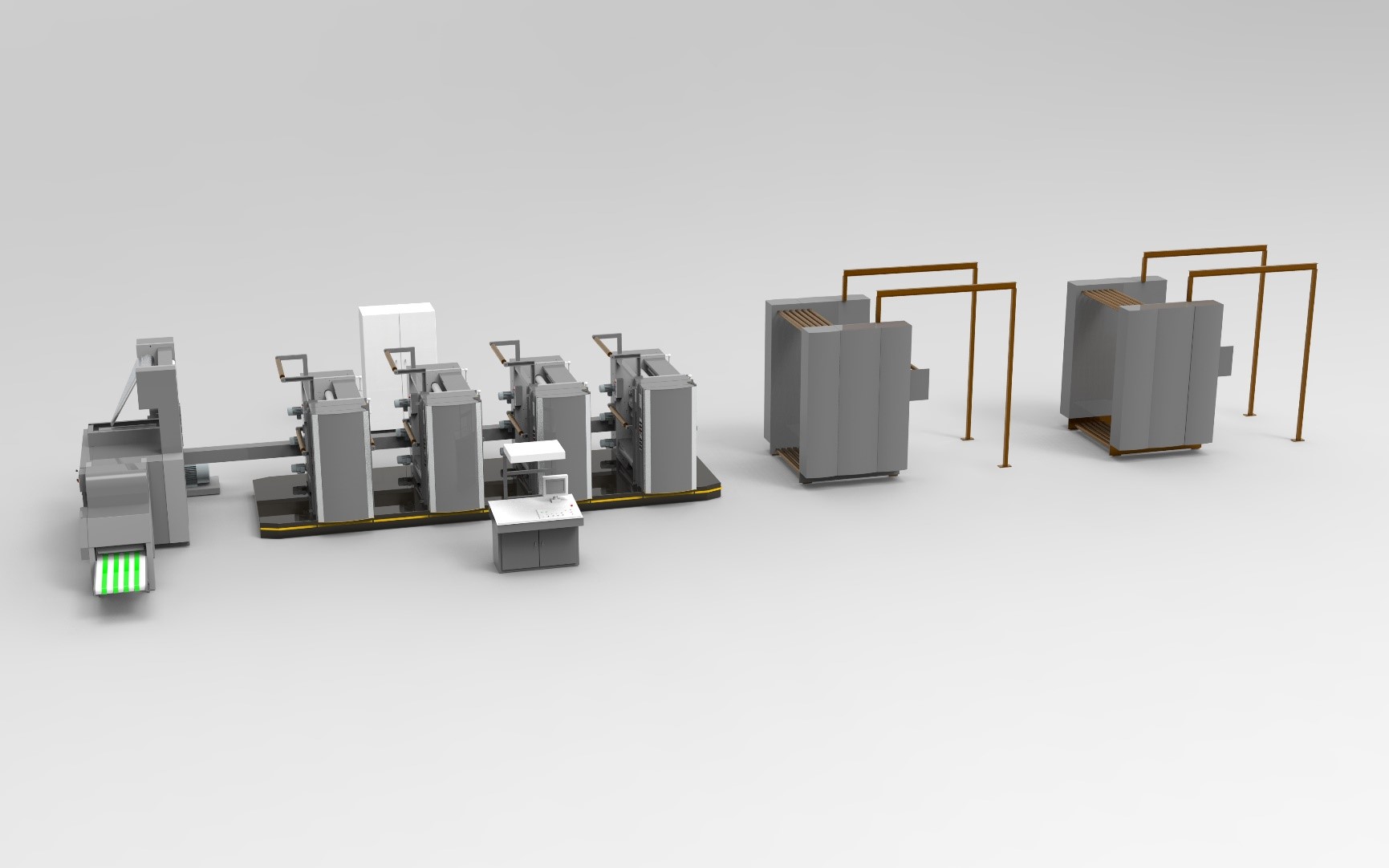

Good news has been reported that on April 23, 2020, Qingdao Solna Electric Co., Ltd. signed an order contract for a SS787K—4—F290 (550) web offset printing press with Dongtai printing customers. Users are satisfied with the operating efficiency and printing quality of the on-site prototype, and signed a contract for ordering the machine with Solna Electric on the spot. The lead time for this order is one month. Next, Solna Electric will seize the time to arrange production and assembly, and deliver high-quality printing machines to customers in time.

Ss787k-4 web lithography printing machine is b-b double-sided double-sided printing machine with cutting specification of 550mm.The machine adopts the design concept of modularization, which is basically composed of a zero-speed automatic paper receiving machine, four b-b printing units, a multi-function integrated folding machine and other ancillary devices.

Ss787k-4 structure features:

1. Modular design of printing unit, compact structure, reasonable layout, convenient and simple maintenance and after-sales service.

2. Pillow-roller contact printing to reduce the impact of gear and bearing clearance and plate head vibration on the printing quality.

3. The roller bearing is supported by a high-precision tapered roller bearing with pretension, which ensures smooth operation and stable pressure.

4. After surface treatment, the printing drum is rust-proof, anticorrosive and wear-resistant.

5 version of the drum with a narrow slot card version, rubber drum with a worm worm rubber winding device.

6. Standard solna key ink bucket, intuitive ink supply, quick adjustment.Solna remote control ink bucket is optional to increase ink tracking curve, making operation more convenient and saving manpower.

7. Anilox roller continuous transfer of ink, suitable for high speed printing.

8. Brush roller continuous water supply structure to prevent back ink.

9. The circumferential and axial printing registration adopts electric plate adjustment, realizing centralized control of the operating platform, convenient operation, rapid and accurate overprinting.

10. Pneumatic control is adopted for the clutch of roller and ink roller.

11. The operating surface of the printing unit is designed with a double-layer protective cover, making the equipment easy to maintain.

12. The electrical control system and gas system are mostly from well-known foreign brands.

13 drum folding machine, diameter ratio 1:2:2:2, folio easy to adjust, stable performance, low noise.

14. The folding machine is equipped with horizontal and vertical punching device, counting, electric adjustment of the paper tape and other functions, folding paste continuous output.

15. Equipped with zero-speed paper feeder, designed with no transmission shaft connection to the main machine, flexible and optional.

16. 32 open folding upgraded to solna special 32 open folding, faster, more efficient, better stability.

17. Folding machine triangle board with air pump, so that there is a layer of air cushion between printing and triangle board, to prevent printing rubbing dirty.